Vertical axis wind turbine

Vertical axis wind turbine

The world's tallest vertical-axis wind turbine, in Cap-Chat, QuebecVertical-axis wind turbines (VAWTs) are a type of wind turbine where the main rotor shaft is set vertically and the main components are located at the base of the turbine. Among the advantages of this arrangement are that generators and gearboxes can be placed close to the ground, which makes these components easier to service and repair, and that VAWTs do not need to be pointed into the wind.[1] Major drawbacks for the early designs (Savonius, Darrieus and giromill) included the pulsatory torque that can be produced during each revolution and the huge bending moments on the blades. Later designs solved the torque issue by using the helical twist of the blades almost similar to Gorlov's water turbines.

A VAWT tipped sideways, with the axis perpendicular to the wind streamlines, functions similarly. A more general term that includes this option is "transverse axis wind turbine". For example, the original Darrieus patent [2], includes both options.

Drag-type VAWTs, such as the Savonius rotor, typically operate at lower tipspeed ratios than lift-based VAWTs such as Darrieus rotors and cycloturbines.

[edit] General aerodynamics

[edit] General aerodynamics

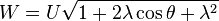

The forces and the velocities acting in a Darrieus turbine are depicted in figure 1. The resultant velocity vector, , is the vectorial sum of the undisturbed upstream air velocity, , and the velocity vector of the advancing blade, .

Thus, the oncoming fluid velocity varies, the maximum is found for  and the minimum is found for

and the minimum is found for  , where θ is the azimuthal or orbital blade position. The angle of attack, α, is the angle between the oncoming air speed, W, and the blade's chord. The resultant airflow creates a varying, positive angle of attack to the blade in the upstream zone of the machine, switching sign in the downstream zone of the machine.

, where θ is the azimuthal or orbital blade position. The angle of attack, α, is the angle between the oncoming air speed, W, and the blade's chord. The resultant airflow creates a varying, positive angle of attack to the blade in the upstream zone of the machine, switching sign in the downstream zone of the machine.

and the minimum is found for

and the minimum is found for  , where θ is the azimuthal or orbital blade position. The angle of attack, α, is the angle between the oncoming air speed, W, and the blade's chord. The resultant airflow creates a varying, positive angle of attack to the blade in the upstream zone of the machine, switching sign in the downstream zone of the machine.

, where θ is the azimuthal or orbital blade position. The angle of attack, α, is the angle between the oncoming air speed, W, and the blade's chord. The resultant airflow creates a varying, positive angle of attack to the blade in the upstream zone of the machine, switching sign in the downstream zone of the machine.From geometrical considerations, the resultant airspeed flow and the angle of attack are calculated as follows:

[3]

[3]where  is the tip speed ratio parameter.

is the tip speed ratio parameter.

is the tip speed ratio parameter.

is the tip speed ratio parameter.The resultant aerodynamic force is decomposed either in lift (F_L) - drag (D) components or normal (N) - tangential (T) components. The forces are considered acting at 1/4 chord from the leading edge (by convention), the pitching moment is determined to resolve the aerodynamic forces. The aeronautical terms lift and drag are, strictly speaking, forces across and along the approaching net relative airflow respectively. The tangential force is acting along the blade's velocity and, thus, pulling the blade around, and the normal force is acting radially, and, thus, is acting against the bearings. The lift and the drag force are useful when dealing with the aerodynamic behaviour around each blade, i.e. dynamic stall, boundary layer, etc; while when dealing with global performance, fatigue loads, etc., it is more convenient to have a normal-tangential frame. The lift and the drag coefficients are usually normalised by the dynamic pressure of the relative airflow, while the normal and the tangential coefficients are usually normalised by the dynamic pressure of undisturbed upstream fluid velocity.

A = Surface Area

The amount of power, P, that can be absorbed by a wind turbine.

Where Cp is the power coefficient, ρ is the density of the air, A is the swept area of the turbine, and ν is the wind speed.[4]

[edit] Advantages of vertical axis wind turbines

VAWTs offer a number of advantages over traditional horizontal-axis wind turbines (HAWTs). They can be packed closer together in wind farms, allowing more in a given space. This is not because they are smaller, but rather due to the slowing effect on the air that HAWTs have, forcing designers to separate them by ten times their width.[5] [6]

VAWTs are rugged, quiet, omni-directional, and they do not create as much stress on the support structure. They do not require as much wind to generate power, thus allowing them to be closer to the ground. By being closer to the ground they are easily maintained and can be installed on chimneys and similar tall structures.[7]

[edit] Disadvantages of vertical axis wind turbines

Some disadvantages that the VAWTs possess are that they have a tendency to stall under gusty winds. VAWTs have very low starting torque, as well as dynamic stability problems. The VAWTs are sensitive to off-design conditions and have a low installation height limiting to operation to lower wind speed environments.[8]

The blades of a VAWT are prone to fatigue as the blade spins around the central axis. The vertically oriented blades used in early models twisted and bent as they rotated in the wind. This caused the blades to flex and crack. Over time the blades broke apart and sometimes leading to catastrophic failure. Because of these problem, Vertical axis wind turbines have proven less reliable than horizontal-axis wind turbines (HAWTs).[9]

Research programmes (in 2011) have sought to overcome the inefficiencies associated with VAWTs by reconfiguration of turbine placement within wind farms. It is thought that, despite the lower wind-speed environment at low elevations, "the scaling of the physical forces involved predicts that [VAWT] wind farms can be built using less expensive materials, manufacturing processes, and maintenance than is possible with current wind turbines"

2nd Guide

Vertical-axis wind turbines

Vertical-axis wind turbines (or VAWTs) have the main rotor shaft arranged vertically. Key advantages of this arrangement are that the turbine does not need to be pointed into the wind to be effective. This is an advantage on sites where the wind direction is highly variable, for example when integrated into buildings. The key disadvantages include the low rotational speed with the consequential higher torque and hence higher cost of the drive train, the inherently lower power coefficient, the 360 degree rotation of the aerofoil within the wind flow during each cycle and hence the highly dynamic loading on the blade, the pulsating torque generated by some rotor designs on the drive train, and the difficulty of modelling the wind flow accurately and hence the challenges of analysing and designing the rotor prior to fabricating a prototype.[citation needed]

Vertical-axis wind turbines (or VAWTs) have the main rotor shaft arranged vertically. Key advantages of this arrangement are that the turbine does not need to be pointed into the wind to be effective. This is an advantage on sites where the wind direction is highly variable, for example when integrated into buildings. The key disadvantages include the low rotational speed with the consequential higher torque and hence higher cost of the drive train, the inherently lower power coefficient, the 360 degree rotation of the aerofoil within the wind flow during each cycle and hence the highly dynamic loading on the blade, the pulsating torque generated by some rotor designs on the drive train, and the difficulty of modelling the wind flow accurately and hence the challenges of analysing and designing the rotor prior to fabricating a prototype.[citation needed]With a vertical axis, the generator and gearbox can be placed near the ground, using a direct drive from the rotor assembly to the ground-based gearbox, hence improving accessibility for maintenance.

When a turbine is mounted on a rooftop, the building generally redirects wind over the roof and this can double the wind speed at the turbine. If the height of the rooftop mounted turbine tower is approximately 50% of the building height, this is near the optimum for maximum wind energy and minimum wind turbulence. It should be borne in mind that wind speeds within the built environment are generally much lower than at exposed rural sites.[citation needed]

[edit] Subtypes

- Darrieus wind turbine

- "Eggbeater" turbines, or Darrieus turbines, were named after the French inventor, Georges Darrieus.[17] They have good efficiency, but produce large torque ripple and cyclical stress on the tower, which contributes to poor reliability. They also generally require some external power source, or an additional Savonius rotor to start turning, because the starting torque is very low. The torque ripple is reduced by using three or more blades which results in greater solidity of the rotor. Solidity is measured by blade area divided by the rotor area. Newer Darrieus type turbines are not held up by guy-wires but have an external superstructure connected to the top bearing.[citation needed]

- Giromill

A subtype of Darrieus turbine with straight, as opposed to curved, blades. The cycloturbine variety has variable pitch to reduce the torque pulsation and is self-starting.[18] The advantages of variable pitch are: high starting torque; a wide, relatively flat torque curve; a lower blade speed ratio; a higher coefficient of performance; more efficient operation in turbulent winds; and a lower blade speed ratio which lowers blade bending stresses. Straight, V, or curved blades may be used.[citation needed]

A subtype of Darrieus turbine with straight, as opposed to curved, blades. The cycloturbine variety has variable pitch to reduce the torque pulsation and is self-starting.[18] The advantages of variable pitch are: high starting torque; a wide, relatively flat torque curve; a lower blade speed ratio; a higher coefficient of performance; more efficient operation in turbulent winds; and a lower blade speed ratio which lowers blade bending stresses. Straight, V, or curved blades may be used.[citation needed]

- Savonius wind turbine

- These are drag-type devices with two (or more) scoops that are used in anemometers, Flettner vents (commonly seen on bus and van roofs), and in some high-reliability low-efficiency power turbines. They are always self-starting if there are at least three scoops.

- Twisted Savonius

- Twisted Savonius is a modified savonius, with long helical scoops to give a smooth torque, this is mostly used as roof windturbine or on some boats (like the Hornblower Hybrid).